Home / What We Do

Industrial Engineering Services

ABOUT ENGINEERING

SCEIFR offering complete range of services to our value customers in various segments including Oil & Gas, Refineries, Petrochemical, Fertilizer, Steel and Power companies.

- PLANT MAINTENANCE AND SERVICES

- HIGH PRESSURE JETTING WORK

- CATALYST HANDLING

- PIPELINE CLEANING SERVICES

- BUNDLE PULLING

- MECHANICAL SUPPORT WORKS

- RENTAL SERVICES

PLANT MAINTENANCE AND SERVICES

We are a “Solutions” provider for plant turnarounds, and on-site maintenance requirements Our projects team are handpicked to custom fit the client requirements, enabling more efficient mobilization and on-time execution with a vast amount of equipment and experienced multi-disciplinary in-house skilled team, we work 24/7 to complete a turnaround with minimum downtime, within budget, and without incidents.

Our range to complete the shutdown with the following services,

- COMPLETE ISOLATION

- ALL MECHANICAL COMPLETION

- CLEANING HYDRO-BLASTING

- EQUIPMENT OVERHAULING

- SLUDGE HANDLING & TRANSPORTATION

- COMPLETE TORQUEING

HIGH PRESSURE JETTING WORK

Hydro jetting machines are range between 10,000-40,000 PSI can be deployed for all equipment’s for cleaning work. All are calibrated pressure gauges and relief valves.Trained operators and hydro jetters are utilized for hydro jetting work.

Our following cleaning range services.

- LANCING MACHINE

- INSIDE BUNDLE CLEANING

- LANCE TUBE CLEANING

- OUTSIDE BUNDLE CLEANING

- TRIPLE LANCE TUBE CLEANING

- HEAT EXCHANGER TUBES CLEANING (INTERNAL/EXTERNAL)

- FIN FAN TUBES EXTERNAL CLEANING (FOAM)

- VESSELS/DRUMS SHELL CLEANING

CATALYST HANDLING

SCEIFR can execute catalyst projects efficiently and safely, with minimal delays from fusing, minimal catalyst arion, and excellent dust control systems. We have highly experienced and trained professionals to perform catalyst handling services in all reactors, reformers, vessels etc.

- COMPLETE CATALYST HANDLING WITH CONVENTIONAL METHOD SOCK OR DENSE LOADING

- UNLOADING AND LOADING OF SINGLE AND MULTI-BED REACTORS

- CATALYST REPLACEMENT IN INERT AND TOXIC ATMOSPHERES, PLUS HOT AND HOSTILE ENVIRONMENTS

- DENSE PHASE LOADING SYSTEMS FOR THE TRANSFER OF CATALYST DIRECTLY FROM THE TOP MANWAY, WITHOUT THE USE OF CRANES AND HOPPERS

- CATALYST WEIGHTAGE, DE-DUSTING, TRANSPORTATION, SEALED STORAGE AND LABELED

PIPELINE CLEANING SERVICES

SCEIFR provides most advance pipeline cleaning services also known as Hydro-milling, Aqua-Milling or Aqua-Lazing, uses of high flow, high-pressure pump to feed water to the cleaning nozzles. The flow and pressure of the water system for De-coking, de-curding, removal of hard deposits such as polymers, Resins and hard crude deposits.

We can clean pipes from 4” (inches) up to 60” (inches) diameter and up to length of 200 Meters without having to cut the pipeline or flanges such as 45/90-degree elbows, bends.

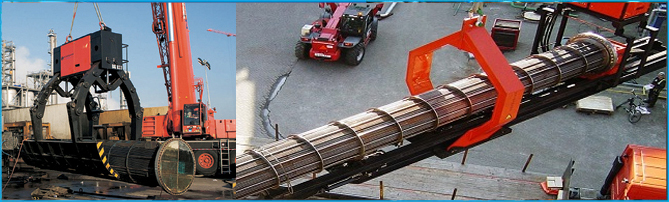

BUNDLE PULLING

SCEIFR provides automated bundle pulling equipment that can pull tube bundle from the shell and transport it to the wash area for cleaning and after overhauling re-install the bundle back into the shell once the maintenance is complete.

- THE AERIAL TUBE BUNDLE EXTRACTOR IS SUITABLE FOR PULL/INSERTING MAX UP TO 2-METER DIA, 12-METER LENGTH AND MAXIMUM OF 45 TON

MECHANICAL SUPPORT WORKS

SCEIFR provides modifications & engineering design services to an existing industrial plant to improve features and increase the overall capacity usually by replacing items of equipment.

- REPLACEMENT OF STATIONARY EQUIPMENT

- REPLACEMENT OF STATIONARY EQUIPMENT

RENTAL SERVICES

INDUSTRIAL SUPER SUCKER

- FLOW RATE 9000 M3/HR, TANK CAPACITY 10 M3

HYDRO JETTING MACHINE

- HIGH PRESSURE/-HOT WATER JETTING UNIT RATED FOR 16GPM AT 10,000NPSI WITH TEMPERATURES AVAILABLE UP TO 1800F

- HIGH PRESSURE JETTING UNIT RATED FOR 16 GPM TO 39GPM AT 10,000 PSI

- HYDRO BLASTER – CONTAINERIZED – 22GPM, 20,000 PSI

- HIGH PRESSURE PUMP – 22GPM, 20,000 PSI

- HIGH PRESSURE PUMP – 22 GPM, 36,000 PSI

VACUUM TANKER/HEAVY DUTY INDUSTRIAL SUPER SUCKER 06″ (STAINLESS STEEL):

- 6,000 CU.MT/MIN. CAPACITY

- 3,400 CU. MT/MIN. CAPACITY

- 2,600 CU. MT/MIN. CAPACITY

WATER TANKER 26 M3 STORAGE CAPACITY.

AIR CONDITIONER 20T + MAXIMUM 50 MTS A/C DUCT

AIR CONDITIONER 40T + MAXIMUM 50 MTS A/C DUCT

DEWATERING PUMP – CENTRIFUGAL 350 CU.MTR/HR

DEWATERING PUMP – SUBMERSIBLE 150-200 CU.MTR/HR

GENERATOR 25 KVA – 160 KVA

SKILLED MANPOWER

- PIPEFITTER

- SAFETY OFFICER

- HYDRO-JETTER

- CATALYST TECHNICIAN

- HELPER / LABOR